Carleton Dairies Ltd, Oxford

...

Owner

Phil Wells

The Challenge:

Ageing Shed Strains Efficiency

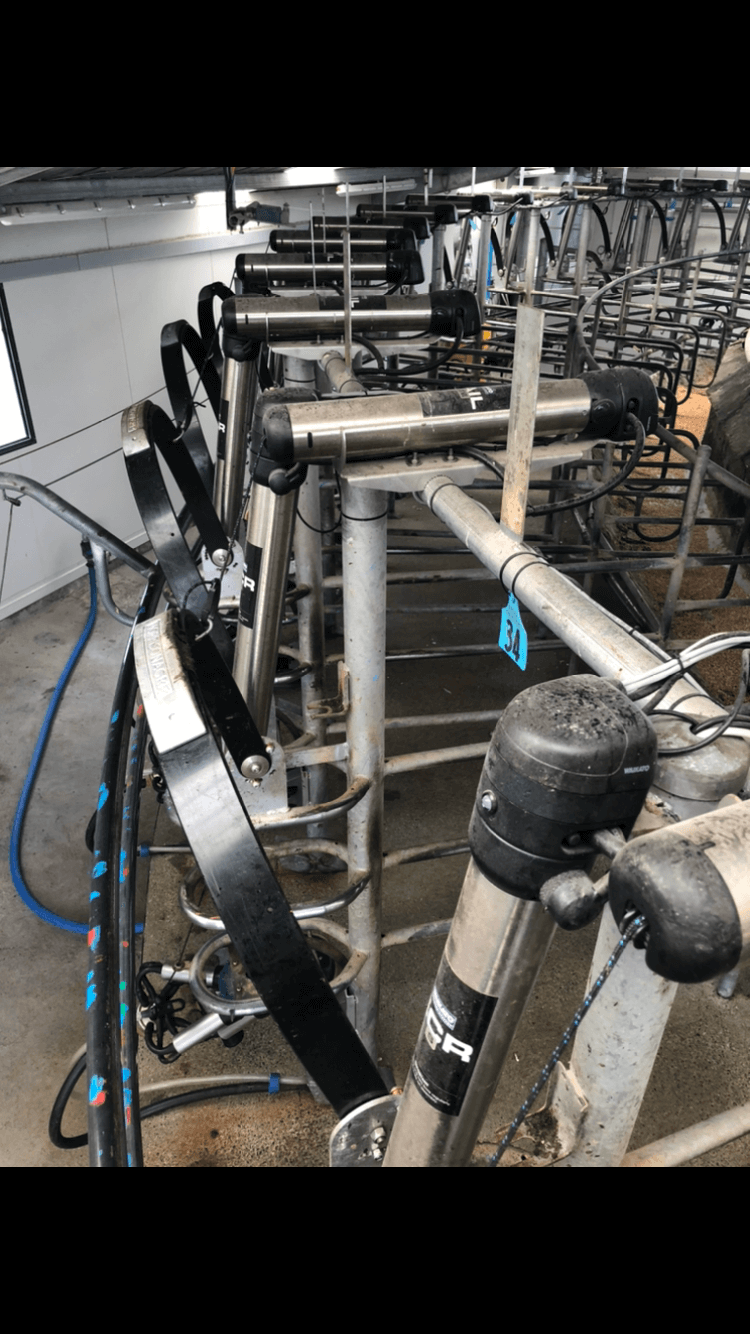

An ageing and labour intensive rotary milking shed which was struggling to keep up with the 1100 cows it had to milk from its 320-hectare farm. Morrison Agri was approached to drastically improve their labour efficiencies. The milking system was assessed to see where time and labour savings could be made.

The Morrison Agri Solutions:

Morrison Agri Streamlines Milking

Identifying key bottlenecks in the milking system efficiencies. Morrison Agri set about:

- Installing Waikato brand ‘S’ cup removers

- Installed the Autostart feature which allows the milker to simply lift the claw and then apply the cups. In a normal milking situation with autostart, there are no buttons to push or flick. The manual switch is still fitted to the bail post to allow for the manual milking option (red cows, kicking cows, colostrum cows) and wash mode.

- Installing new strap type automated bail gates

- Installing the Waikato brand SmartSPRAY automatic teat spray system for rotary sheds which is controlled by the ‘S’ cup remover.

The Outcomes:

Labour Reduction, Enhanced Accuracy

A vastly improved milking operation with fewer labour requirements and accurate cluster removal.

The SmartSPRAY also acts as a pre-milking leg spreader for cows, making cupping easier and very accurate teat spraying soon after the cups have been removed.

The client was thrilled with the improvements made and the resulting decrease in labour intensity.